Everything about Armoured Cable Gland

What is armoured cable gland?

Under IEC standards, there are two main cable gland types according to mechanical properties, which are non-armoured cable gland and armoured cable gland.

This main difference between unarmored and armoured cable gland is that the armoured cable gland are designed for use with steel-wired armoured (SWA) cables.

What is armoured cable?

What is armoured cable?

In electrical power distribution, armoured cable usually means steel wire armoured cable (SWA) which is a hard-wearing power cable designed for the supply of mains electricity.

The swa cable are made of conductor,insulation, bedding, armour and sheath

Different from unarmored cable, the armoured cable has added protective armour that helps protect the cable core.

Main functions of armoured cable glands:

1.Protection from the environment – seals the cable’s outer sheath to prevent dust, particles and moisture from the electrical box or enclosure.

2.Earth continuity – if the armoured cable gland is metallic in construction, it can be tested for earth continuity.

3.Securing the cable – provides resistance against cable pull-outs when the cable is impacted.

4.Complex sealing – armoured cable glands offer substantial ingress protection for the part of the cable that enters electrical boxes or enclosures.

Usually the use environment of armoured cable glands will be worse than that of unarmoured cable glands, due to armoured cables always be buried directly underground, for outdoor installation or in tunnels.

Therefore, it’s important to install the armoured cable glands correctly, you can click here to see our article on“how to install an armoured cable gland?”

Jixiang Connector is a professional manufacture of various kinds of cable glands and cable connectors.

Jixiang Connector is a professional manufacture of various kinds of cable glands and cable connectors.

You can find the most common type armoured cable gland as below:

BW Cable Gland

BW cable glands suitable for single wire armored, plastic or rubber sheathed cable. Recommended to use with shroud for additional ingress protection.

CW Cable Gland

CW cable glands is used for outdoor applications, terminates and secure cable armoring and outer seal grips sheath of cable thus ensuring mechanical strength and earth continuity and where necessary to provide an IP66 seal with the outer sheath of the cable.

Any inquire of armoured cable gland, you can contact us directly. Our team are ready to provide the perfectly suitable solution.

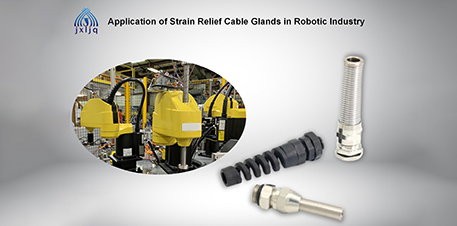

What is Strain Relief Cable Glands?

Strain relief cable glands also known as spring cable gland,is wave-guide designed and could protect the entry conduits and cables to avoid bending, it reaches IP68 degree waterproof function with strong sealing.

Strain relief cable glands are a compression fitting or cable entry, leads the cable into the housing in a sealed and strain-relieved manner.

Considering that the robot's cables are often subject to repeated bending, twisting and mechanical stress, if not properly protected, it can lead to cable failure, using strain relief cable glands are the perfect solution.

Strain relief cable glands are designed with a spiral flexible protector, can around the cord and adds strength to the cord where it is most vulnerable to damage, provides long-term effective cable protection, reducing maintenance costs and downtime and repair costs due to cable damage.

In addition, It is very simple to install the strain relief cable glands, simply insert cable through the assembled gland and tighten gland lock until cable is secured.

What is Strain Relief Cable Glands?

Strain relief cable glands also known as spring cable gland,is wave-guide designed and could protect the entry conduits and cables to avoid bending, it reaches IP68 degree waterproof function with strong sealing.

Strain relief cable glands are a compression fitting or cable entry, leads the cable into the housing in a sealed and strain-relieved manner.

Considering that the robot's cables are often subject to repeated bending, twisting and mechanical stress, if not properly protected, it can lead to cable failure, using strain relief cable glands are the perfect solution.

Strain relief cable glands are designed with a spiral flexible protector, can around the cord and adds strength to the cord where it is most vulnerable to damage, provides long-term effective cable protection, reducing maintenance costs and downtime and repair costs due to cable damage.

In addition, It is very simple to install the strain relief cable glands, simply insert cable through the assembled gland and tighten gland lock until cable is secured.

Jixiang Connector are the professional manufacturer and provide strain relief cable glands in nickel-plated brass and nylon to meet different requirement.

Any inquire or questions, welcome to contact us directly, our team will offer advice and recommend the best cable glands for your application.

Jixiang Connector are the professional manufacturer and provide strain relief cable glands in nickel-plated brass and nylon to meet different requirement.

Any inquire or questions, welcome to contact us directly, our team will offer advice and recommend the best cable glands for your application.

Condsider the IP Rating of Nylon Cable Glands

The main function of nylon cable glands are used to firmly secure electrical cable entering a piece of equipment, and provide a seal between the external and internal surfaces of the equipment, choose high level IP rating is important.

An IP Rating represents the level of protection provided by a device against the intrusion of solid objects and liquids.

The most common IP ratings of nylon cable glands are probably 65,66,67 and 68, you can find the defined as below for quick reference.

IP65 - IP rated as "dust tight" and protected against water projected from a nozzle.

IP66 - IP rated as "dust tight" and protected against heavy seas or powerful jets of water.

IP67 - IP rated as "dust tight" and protected against immersion. for 30 minutes at depths 150mm - 1000mm

IP68 - IP rated as "dust tight" and protected against complete, continuous submersion in water.

Jixiang Connector nylon cable glands can reach IP68 level and rasistant to salt water, weak acid, alcohol, oil, grease, and common solvency.

Condsider the IP Rating of Nylon Cable Glands

The main function of nylon cable glands are used to firmly secure electrical cable entering a piece of equipment, and provide a seal between the external and internal surfaces of the equipment, choose high level IP rating is important.

An IP Rating represents the level of protection provided by a device against the intrusion of solid objects and liquids.

The most common IP ratings of nylon cable glands are probably 65,66,67 and 68, you can find the defined as below for quick reference.

IP65 - IP rated as "dust tight" and protected against water projected from a nozzle.

IP66 - IP rated as "dust tight" and protected against heavy seas or powerful jets of water.

IP67 - IP rated as "dust tight" and protected against immersion. for 30 minutes at depths 150mm - 1000mm

IP68 - IP rated as "dust tight" and protected against complete, continuous submersion in water.

Jixiang Connector nylon cable glands can reach IP68 level and rasistant to salt water, weak acid, alcohol, oil, grease, and common solvency.

Consider the UL94 Classification of Nylon Cable Glands

UL 94, the Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances testing, is a plastics flammability standard released by Underwriters Laboratories of the United States.

UL94 HB/V material will be rated:

V-0: if flame extinguishes within 10 seconds with no dripping

V1: if flame extinguishes within 30 seconds with no dripping

V2: if flame extinguishes within 10 seconds with dripping

Consider the UL94 Classification of Nylon Cable Glands

UL 94, the Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances testing, is a plastics flammability standard released by Underwriters Laboratories of the United States.

UL94 HB/V material will be rated:

V-0: if flame extinguishes within 10 seconds with no dripping

V1: if flame extinguishes within 30 seconds with no dripping

V2: if flame extinguishes within 10 seconds with dripping

Consider the UV-resustant of Nylon Cable Glands

UV resistance, known as photodegradation, refers to a substance’s ability to avoid degradation caused by the absorption of UV radiation.

When you design components for outdoor use and industrial applications generally require higher UV resistant nylon cable glands to maintain optimal quality and performance.

Using the UV-resistant nylon cable glands will not typically change in appearance be in through yellowing, leaching dye color, bleaching, or the formation of stress cracks and hardness, and will not become brittle.

Jixiang Connector can customize UV-resistant nylon cable glands, are great candidates for outdoor applications use.

Consider the UV-resustant of Nylon Cable Glands

UV resistance, known as photodegradation, refers to a substance’s ability to avoid degradation caused by the absorption of UV radiation.

When you design components for outdoor use and industrial applications generally require higher UV resistant nylon cable glands to maintain optimal quality and performance.

Using the UV-resistant nylon cable glands will not typically change in appearance be in through yellowing, leaching dye color, bleaching, or the formation of stress cracks and hardness, and will not become brittle.

Jixiang Connector can customize UV-resistant nylon cable glands, are great candidates for outdoor applications use.

Nylon cable cable gland for outdoor use are easily affected by wind, rain, ice, snow and environmental climate, due to their working conditions are harsh. Jixiang Connector is a professional manufactuer of nylon cable glands, not only offer high quality and durable cable glands, but also provide custom services to suit every environment use.

Any questions or inquiry, please don’t hesitate to contact us.

Nylon cable cable gland for outdoor use are easily affected by wind, rain, ice, snow and environmental climate, due to their working conditions are harsh. Jixiang Connector is a professional manufactuer of nylon cable glands, not only offer high quality and durable cable glands, but also provide custom services to suit every environment use.

Any questions or inquiry, please don’t hesitate to contact us.

Classification of stainless steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion.

Stainless steel’s corrosion resistance and mechanical properties can be further enhanced by adding other elements, such as nickel, molybdenum, titanium, niobium, manganese, etc.

There are five main families, which are primarily classified by their crystalline structure: austenitic, ferritic, martensitic, duplex, and precipitation hardening.

The 300-series formulas is a popular choice for a wide variety of cable glands applications. The 304, 316 and 316L stainless steel cable glands are the most commonly specified.

Classification of stainless steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion.

Stainless steel’s corrosion resistance and mechanical properties can be further enhanced by adding other elements, such as nickel, molybdenum, titanium, niobium, manganese, etc.

There are five main families, which are primarily classified by their crystalline structure: austenitic, ferritic, martensitic, duplex, and precipitation hardening.

The 300-series formulas is a popular choice for a wide variety of cable glands applications. The 304, 316 and 316L stainless steel cable glands are the most commonly specified.

What Is The Difference Between 304 And 316 Stainless Steel Cable Glands?

Simply distinguish them, 304 contains 18% chromium and 8% or 10% nickel while 316 contains 16% chromium, 10% nickel and 2% molybdenum. 304L or 316L is their low-carbon versions.

You can find the specific difference between SS304 and SS316 from the table below:

What Is The Difference Between 304 And 316 Stainless Steel Cable Glands?

Simply distinguish them, 304 contains 18% chromium and 8% or 10% nickel while 316 contains 16% chromium, 10% nickel and 2% molybdenum. 304L or 316L is their low-carbon versions.

You can find the specific difference between SS304 and SS316 from the table below:

In different applications,both 304 stainless steel cable glands and 316 stainless steel cable glands have pros and cons to consider.

When exposure to chemicals or a marine environment, 316 stainless steel cable glands is the better choice, due to 316 stainless steel cable glands is more resistant than 304 to salt and other corrosives.

Such as SS316 stainless steels cable glands are required in the manufacture of certain pharmaceuticals in order to avoid excessive metallic contamination.

On the other hand, 304 stainless steel cable glands is a more economical choice, when it doesn’t need strong corrosion resistance.

In different applications,both 304 stainless steel cable glands and 316 stainless steel cable glands have pros and cons to consider.

When exposure to chemicals or a marine environment, 316 stainless steel cable glands is the better choice, due to 316 stainless steel cable glands is more resistant than 304 to salt and other corrosives.

Such as SS316 stainless steels cable glands are required in the manufacture of certain pharmaceuticals in order to avoid excessive metallic contamination.

On the other hand, 304 stainless steel cable glands is a more economical choice, when it doesn’t need strong corrosion resistance.

Jixiang Connector is a professional cable glands manufacturer and provide SS304 and SS316L stainless steel cable glands, available in a variety of thread types, Metric thread, PG thread, NPT thread and G thread, clamping range from 3mm to 90mm suitable for all sizes of cables.

Hope this article was useful and you also can contact us for details.

Our expert team are standing by and ready to help.

Jixiang Connector is a professional cable glands manufacturer and provide SS304 and SS316L stainless steel cable glands, available in a variety of thread types, Metric thread, PG thread, NPT thread and G thread, clamping range from 3mm to 90mm suitable for all sizes of cables.

Hope this article was useful and you also can contact us for details.

Our expert team are standing by and ready to help.